By SoliTek

In 2017 solar modules manufacturers R&D expenditure reached US$967.28 million(1). LONGI group with First Solar spent US$175.5 million and US$88.6 million respectively. European solar modules have small chances to compete internationally without co-operation with limited budget they have. SUPER PV allows to bridge manufacturers with research institutions resulting in creation of new products. 3 European solar module manufacturers are part of SUPER PV project: SoliTek, Apollon Solar and Flisom, each having potential benefits from the innovations being developed within the project.

SoliTek - solar modules manufacturer, one of the initiators of SUPER PV project, have a good grasp of Scandinavia market. This market allows them to compete with international competitors due to market need of high quality modules. Being a manufacturing company inside Europe provides liability and trust for clients within the scope accessibility of information, work of ethics, customer support, etc. compared to companies in Asia. With the help of SUPER PV innovations, SoliTek and Apollon Solar can strengthen their positions in the current markets. In the case of Apollon Solar, the combination of the project innovations with their proprietary N.I.C.E.™ module technology is expected to have a positive impact on positioning high performance modules on selected markets.

Additionally, the demo sites of SUPER PV will allow SoliTek, Flisom and Apollon Solar to test and qualify their innovation modules in Tunisia and Morocco which might allow them in the near future to expand in those markets or markets with similar climatic challenges if the tested innovations are successful. Having evidence that your modules are working in the target market makes accessing that market much smoother.

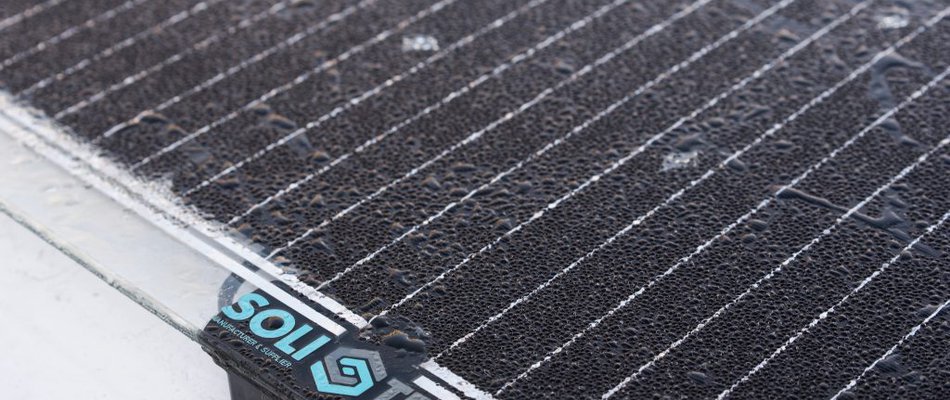

SoliTek modules finding applications outside EU: Glass-glass modules in Dakar Rally. Source: SoliTek.eu

Most of R&D progress of the solar sector occurs in Europe with results being exported. As SoliTek are in-touch of numerous information and aware of new researches about solar modules they decided to initiate consortium idea to combine innovations in order to reduce the LCOE by 26% to 37%. As solar manufacturers with innovations being developed in SUPER PV, they could provide diversified solutions to different regions, from cold and hot climates to dry and wet regions. SoliTek modules have reached Dakar Rally, as seen in picture above. With the innovation of easy to use anti soiling coating, modules could be used more widely in the desert areas.

Solar module manufacturers seem to be polar bears of climate change, the symbol of extinction in the changing environment. As solar module manufacturers in EU are in-touch with various projects they can adapt novel approaches faster compared to non-EU companies. SUPER PV provides benefits to all value chain players and for EU solar modules manufacturers it’s a chance to reduce costs by co-operating and provide competitive solutions to the market.

Due to Asian countries relying on coal plants and large geographical distance for transportation of solar modules, their products have higher CO2 footprints(2). SUPER PV innovations allow to reduce costs of kWh as well as reduce O&M costs which can prolong solar modules effectiveness and lifetime by better maintenance. At the end of the day, these innovations stack up and allow to reduce the CO2 footprint of solar modules. It's a strong opportunity for EU manufactures to increase their modules' eco-design which, in some countries like France, is rewarded in tender projects. With the benefits of SUPER PV, solar module manufacturers in the EU can easier approach markets which have high quality standards, while at the same time decreasing the kWh price.

1. https://www.pv-tech.org/editors-blog/solar-manufacturing-industry-rd-spending-in-2017-hits-new-high

2. https://energypost.eu/solar-consumption-and-manufacturing-can-europe-re-take-the-lead/